Silage Pit Preparations & Effluent Management

Getting your silage pit ready and fit for purpose

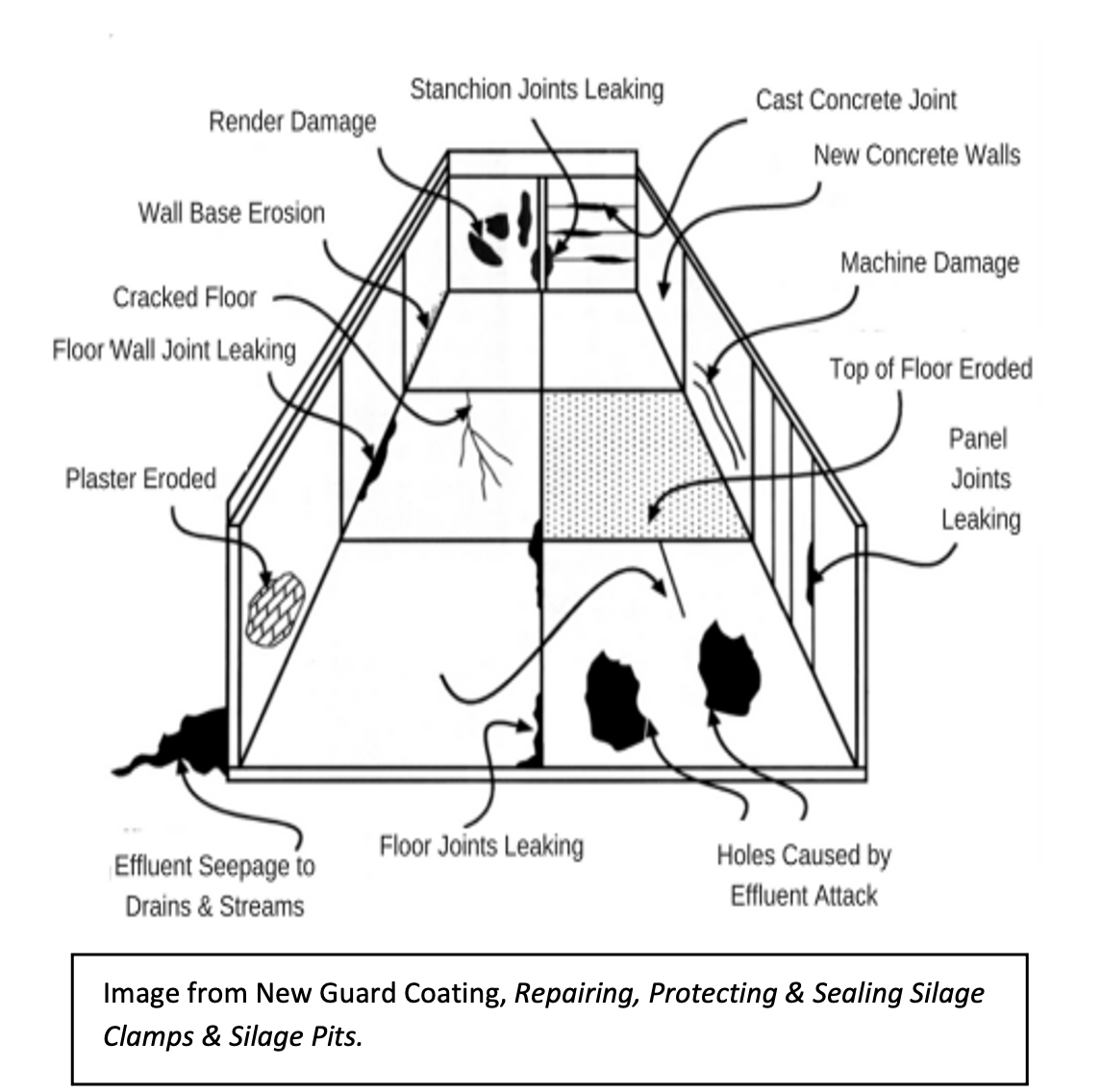

As silage season is nearing, farmers need to start inspecting their silage bases, walls, and storage facilities to ensure they are fit for purpose and up to Department of Agriculture, Food, and the Marine (DAFM) specifications. Regularly inspecting the silage pit ensures that problem areas are resolved when they are minor and manageable. Leaving minor problems for too long can lead to more costly solutions in the future.

Inspection

Wash down the pit area with a power washer to effectively assess the floor and walls. Observe for any cracks in the walls or floor, broken pieces of concrete, dips in the floor, pours areas, and eroded or unsealed joints. Look for holes or cracks in the silo walls, as they are common areas for effluent seepage. Assessing the damage to the floor or walls can be determined by removing any loose concrete at the base of walls and joints. A practical way to assess the structural soundness of the floor is to use a wooded post or fencing stake and bounce it off the floor. If there is a hollow sound, it can indicate that there is effluent seepage that has detreated the foundations of the floor. Ideally, a sharp thud when the wooded post hits the floor indicates a more structurally sound and supported floor.

Repairs

The extent of the damage and condition of the floor will determine the repairs required and the silage pit is fit for purpose. Where there is extensive erosion and cracks to an old silage base, the entire floor and foundation may need to be removed and a new silage base put down. Any work conducted on the silage base must comply with DAFM specifications S128 (specification for concrete silage bases), S128A (specification for resurfacing silo bases), and S120 (specification for concrete walled silo bases).

Where cracks are evident and the sealant in the joints has been pulled out or is no longer bonded to sound concrete, repairs need to be conducted. The size of the crack/joint after cleaning and cutting back to sound concrete, will determine the type of repair needed. If the crack/joint is shallow and narrow, using primer and sealant should be suitable. For floor cracks/joints, hot-poured rubberised bitumen can be effective. Gun-applied sealants, i.e., polyurethane, can be effective when repairing vertical cracks/joints on the silo walls. For larger cracks/joints, the prepared area may be filled with a repair mix consisting of sand, cement, synthetic rubber, or latex called styrene-butadiene resin, or SBR as it is commonly known.

Silage

When cutting silage, allow it to wilt for 24 hours before ensiling. It can reduce the volume of effluent that needs to be collected. It is important not to overfill the silage pit beyond its designed capacity, as effluent issues arise from ensiling silage beyond what the silage pit can hold. Additional silage should be baled or ensiled in another pit or silage slab. The effluent channels should be cleaned out and plastic drainage pipes used. The silage polythene cover should extend past the effluent channels to minimise the collection of rainwater. Silage polythene covers can be draped over the silo walls to further protect and collect the silage effluent when ensiling. The ensiled grass should not extend past or over the effluent channels, and all the effluent should be diverted to a collection tank.

When ensiling grass in wet conditions, it is advisable to use additional drainage pipes to take the pressure off the clamp and reduce the risk of the pit slipping. It is important to slope the grass back 45 degrees from the top of the walls to minimise effluent seepage over the silo wall.

Spreading of silage effluent

Ideally, when land spreading silage effluent, dilute the effluent with one part soil water or slurry to one part silage effluent. The volume of effluent that comes off a ton of grass can vary from 0 to 350 liters. This all depends on the Dry Matter percentage of the silage. For instance, very little to no effluent would be produced from grass with a DM content >25%. Do not apply silage effluent within 2 days of heavy rainfall or if rain is forecast within the next 24 hours. It is important to adhere to the minimum 5m buffer from any watercourse, a 10m buffer where the slope of the field exceeds 10%, and a 20m buffer where main rivers or lakes a present.

Round Bales

Typically, silage bales tend to be wilted longer (30% DM) and do not generate much effluent runoff. Silage bales that have been wilted effectively (approximately 48hrs) can be stored on a hard-core area not within 20m from any watercourse or dry drains. As per DAFM regulations, storage of silage bale in the absence of an effluent collection facility is limited to being staked two high. Where effluent run-off is present or the bales have a lower DM%, a collection facility must be in place. Where silage bales are stored on a concrete surface, there must be a way to collect any effluent from the bales into a storage tank.

In the unlikely event of effluent seepage into a watercourse, it is strongly advised to contact your agricultural or ASSAP advisor and notify both Inland Fisheries Ireland and the Local Authority.

Sustainability Action Payment

Tirlán has committed to assist our dairy suppliers in reducing the carbon footprint, enhancing water quality and improving air quality and soil health of farms in line with our sustainability strategy, Living Proof and Sustainability Action Payment.

First Published 15 May 2023

Tagged with: Dairy