Best Practices for Silage Pit Preparation & First Cut Silage Readiness

As silage season approaches, dairy farmers face the challenge of preparing for the first cut amidst wet and difficult conditions experienced at the start of the year. Despite these challenges, proper preparation is essential to ensure high-quality silage production and maintain adequate feed reserves for the winter months. Included are some best practices to consider.

Early Preparation

Begin preparations well in advance of the harvesting season. Contacting your contractor early to schedule the cutting of silage and ensure you’re placed on their list. It is important that the silage pit is thoroughly cleaned by removing any existing materials and power-washing the floor and walls to ensure cleanliness, which can impact silage quality.

Inspection & Repairs

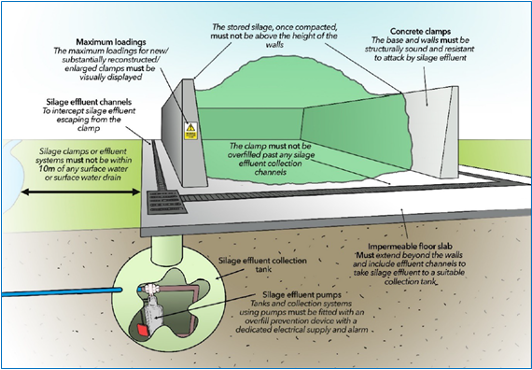

Once the silage pit is cleaned, it is important that it is inspected for cracks, broken concrete, hollows in the floor of the pit and any other visible damage. The structural integrity of silage pits, slabs and walls is key to ensure ensiling occurs within a leak proof enclosure. Additionally, silage effluent collection channels and tank storage should have the capacity to accommodate the total volume of effluent produced. Addressing minor problems promptly will prevent costly repairs in the future. Repairs to any damage of the silage pit should be carried out in accordance with specifications outlined by the Department of Agriculture, Food and the Marine (DAFM) to ensure the silage pit is fit for purpose.

Figure 1. Silage Pit Example - Source: Farming and Water Scotland

Strategic Silage Planning and Risk Management

Assess available stocks meticulously, considering potential deficits resulting from reduced grazing efficiency during the wet conditions earlier in the year. Implement risk management strategies to mitigate the impact of uncertain weather conditions on silage production. Consider alternative feed sources or supplementation options to bridge potential shortfalls in silage reserves.

Nutrient Management

Ensure there is adequate nutrients for land which is being used for silage production by following recommended fertiliser and slurry requirements. Consider the farms soil test results or nutrient management plan to determine the phosphorus (P) and potassium (K) requirements for silage fields. Utilising organic manures such as slurry on silage ground, will allow for a large proportion of crop nutrient requirements at a relatively low cost. Sulphur should also be applied where required (especially on lighter sandy soils), as optimising soil Ph will impact grass yield and quality.

Timely Application

Apply fertilisers and slurry in a timely manner to ensure optimal nutrient uptake by silage crops. Slurry should be spread first, followed by fertiliser with sulphur about a week later if required. Weather conditions should also be monitored closely to identify windows of opportunity for these applications. Where possible, avoid delaying the cutting date due to the poor conditions earlier in the year, as this may lead to feed shortages next winter.

Silage Handling

Allow for silage to wilt for 24 hours before ensiling to reduce effluent volume and ensure optimal preservation. Manage effluent properly by cleaning effluent channels and using plastic drainage pipes. Extend silage polythene covers past effluent channels to minimise rainwater collection. It is also important to not to overfill the silage pit beyond its designed capacity, as this will result in effluent issues. Additional silage should be baled or ensiled in another pit or silage slab.

Round Bales

Typically, silage bales are allowed to wilt for a longer period (reaching approximately 30% Dry Matter content) and consequently produce minimal effluent runoff. Properly wilted silage bales left for 48 hours, can be stored on a firm surface located at least 20 meters away from any watercourse or any drains. According to the DAFM regulations, if silage bales are stored without an effluent system, they should not exceed a height of two bales when stacked.

In cases where effluent occurs or when bales have a lower Dry Matter percentage, it is imperative to have an effluent collection system in place. When silage bales are stored on a concrete surface, provisions must be made to collect any effluent and divert it into a storage tank.

Conclusion

Following these best practices for silage pit preparation and first-cut silage readiness, farmers can ensure high-quality silage production, maintain adequate feed reserves, and mitigate risks associated with adverse weather conditions.

Sustainability Action Payment

Tirlán has committed to assisting our dairy suppliers in reducing the carbon footprint, enhancing water quality and improving air quality, soil health and biodiversity of farms in line with our sustainability strategy, Living Proof and our Sustainability Action Payment. The use of protected urea as part of your fertilizer programme (now counts as 2 actions as part of the action payment), Low Emissions Slurry Spreading for slurry applications, and the implementation of a nutrient management plan are three on-farm actions which can benefit your farm this silage season, while also help you lock in your 0.5cpl (including VAT) Sustainability Action Payment for 2025.

First Published 20 May 2024

Tagged with: Dairy