Making Quality Silage and Fodder Budgeting

The extended indoor feeding period last autumn and again this spring has led to renewed focus on making adequate silage reserves for this season. However, bad weather through Spring 2024 has also delayed closing and fertilizer application on silage ground. Dairy farmers will have to plan carefully to ensure that stocks of adequate quality silage are secured this summer.

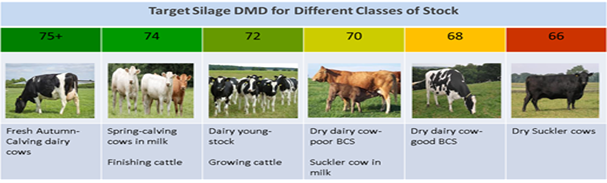

It is important for each farmer to work out what is the best way for his /her farm to secure enough fodder for the winter while avoiding potential issues in securing that fodder. A plan needs to be put in place to work out what type and quantity of fodder is required for each group of animals. · Are all livestock being kept on the farm for the full winter period? · What quality of silage is required for the different livestock groups? · Can I close off extra silage ground and still have grass for the high stocking rate on the farm for a longer time period? · Can I secure external feed sources to make up remaining deficiencies? Prioritise bulk over silage quality As always, the quality (DMD) of silage for each farm plan should be dictated by planned number of each type of stock to be fed next winter. However, given the difficulties experienced on many farms this spring it is likely that a ‘bulk before quality’ mind-set may prevail. This needs to be challenged and the following questions answered by each farmer.

Fertilizer applications for 2nd Cut Silage

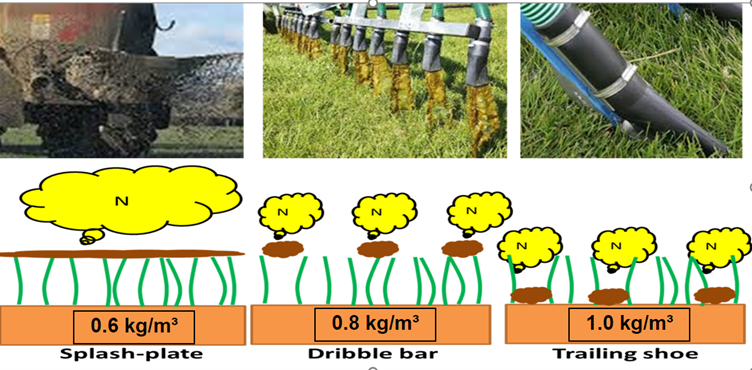

There is plenty of good quality slurry on farms, use this at a rate of 2000-2500g/ac on silage ground. Damp, overcast weather ideal for slurry application. If it receives slurry, apply 65 units/ac (80 Kg/Ha) of Protected Urea and sulphur. If it receives no slurry, apply 75 units/ac (90 Kg/Ha) of Protected Urea plus Sulphur & alternative source of P & K. Aim for an early/mid July cut if possible. As explained at the Tirlan farm walk on the 21st of June in monitor farmer Donal Kavanagh’s farm it is great to get your slurry tested. By doing this you will know the dry matter and the NPK amounts in each 1000 gallons of your slurry. By knowing this information you can cut NPK amounts and top up then the missing requirements for the silage crop. Financially you will save money and at the same time use your own farm nutrients instead of chemical fertiliser. By spreading slurry by LESS you also reduce your greenhouse gas emissions. Remember cutting removes 2.5 times the P and 10 times the K more than grazing so remember to replace these nutrients to maintain soil fertility levels.

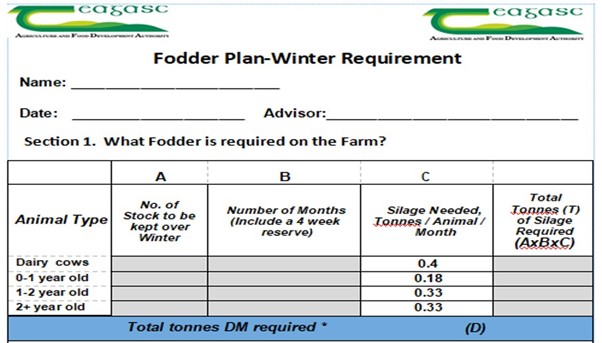

Final Step: Complete a winter forage budget plan for the farm

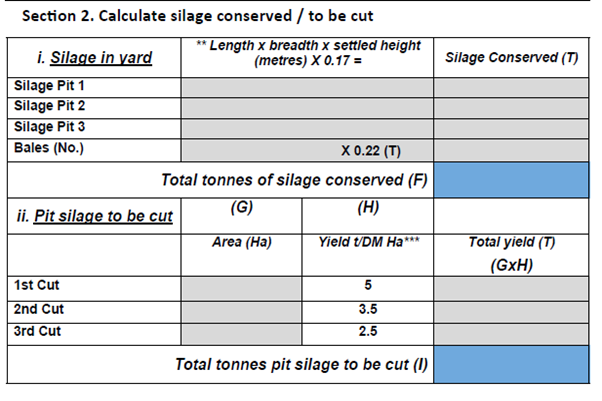

The first exercise that a farmer should carry out in a fodder budget is to determine the amount of silage required on the farm. The next exercise is to determine how much silage is in the yard and the below table will make this position clear. The fodder situation may need to be revaluated on the farm in the event of an early winter. When animals are housed early, your requirement for silage will have increased accordingly

Where a fodder deficit is identified, it is imperative to act early to avoid a situation where silage stocks run out completely on the farms. As part of this plan, you may need to consider offloading non-productive or marginal stock to reduce demand before the onset of winter next year. Carrying lower grade stock on very expensive silage is difficult to justify. Selling poor performers, high SCC, lame or late calving cows has the potential to reduce any deficit or increase the reserve on farm. For each cow sold now 25 ton additional silage will be available next winter. This is halved to 12.5 ton of a saving if these cows remain on farm until next September.

If there is a silage deficit and this deficit is being met by ration supplementation, it’s important that there is sufficient head room for all the animals to feed at the same time. There are many computer programs to help famers to carry out a fodder budget. My advice is to get one completed. These programmes take into account various factors including days of concentrate supplementation and dry matter of the silage. Author: Sandra Hayes Coordinator of the Teagasc Tirlán Future Farm Programme

First Published 03 July 2024

Tagged with: Dairy